SERVICE

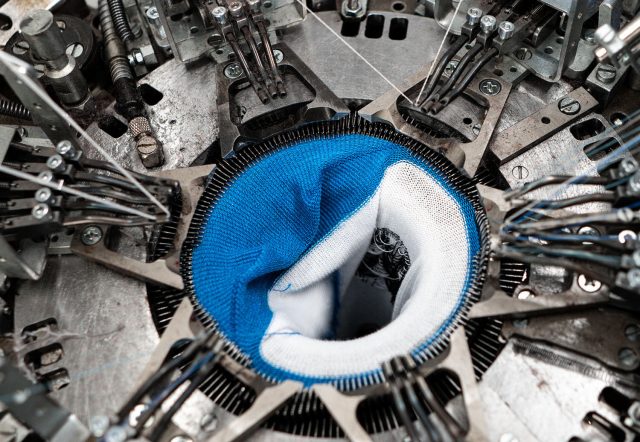

We aim for your machines to function flawlessly for decades, prioritizing regular maintenance, and we’re pleased to offer it, ensuring well-tuned knitting machines that consistently deliver high-quality socks.

We employ a regimen of preventive, predictive, and proactive inspections to prevent repairs, carefully scheduled according to your preferences.

In cases of unexpected machine issues, even experienced sock manufacturers understand that swift adjustments can be crucial. That’s why, in addition to routine inspections, having a ‘reliable advisor on call’ is essential for quick guidance or on-site adjustments when needed.

TRAINING

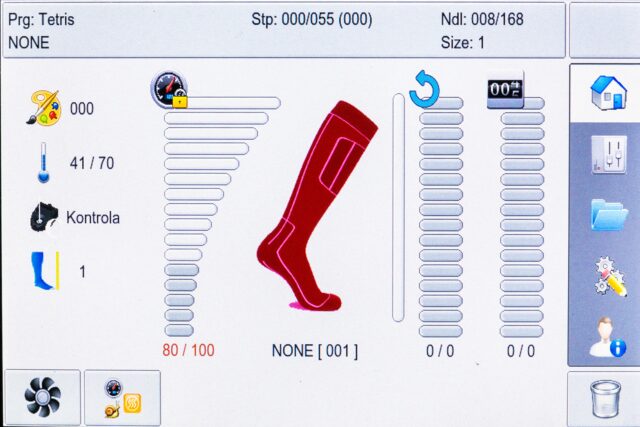

Have you purchased a machine, got it fully installed, but are unsure about its operation?

We’re here to help tailor a training program to meet your needs and the needs of your team. Each socks-knitting factory and knitting team brings unique experiences, so we approach training on an individual basis.

Our experts have decades of experience and are enthusiastic about passing on their knowledge.

Prefer on-site training? No problem. We can come to your new knitting facility and provide training right there. However, if you’d like to visit us, you can also receive training at our Radisox socks-knitting factory in Hořovice.

SPARE PARTS

If you own a knitting machine, you’re likely familiar with the frustration that follows when a machine component breaks. Orders and deliveries can often take weeks, causing production delays, order constraints, and possible penalties for late deliveries.

So, we posed a question to ourselves: ‘Why wait for weeks to months for a spare part when we can have a new one within days?’

We’re delighted to have our own in-house facility for manufacturing spare parts. We maintain stock for frequently used components, and for the less common ones, we can produce them on demand. Simply get in touch with us.

EQUIPMENT FOR FACILITY

Equipping Your New Knitting Factory?

Do you have a well-defined business plan but find yourself uncertain about the most suitable machinery, training timing, and subsequent steps once the knitting machines are operational? We’re here to guide you through the entire process, from facility selection to full knitting factory outfitting.

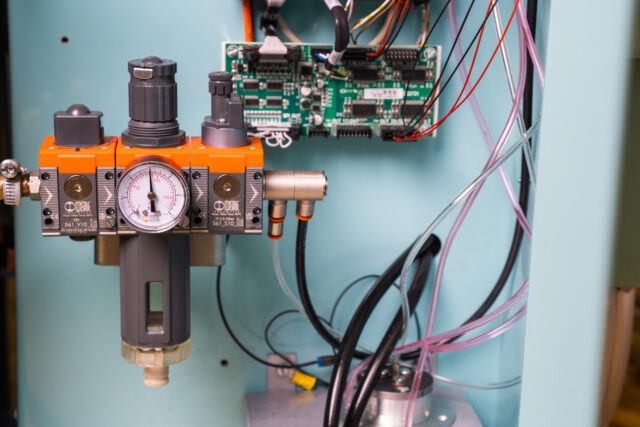

Our goal is to create a customized knitting factory tailored to your specific needs and to establish ideal conditions for your knitting operations. We can also assist in sourcing yarn, tools, air conditioning, compressors, or blowguns through trusted suppliers.

In essence, you won’t be navigating this journey alone – we’re here to support you every step of the way.

EFFICIENT SUPPORT 7/7

In today’s era of technological advancements, particularly the internet, you can expect to receive assistance more swiftly than ever before.

Gone are the days of waiting for extended periods, sometimes weeks, for someone to arrive and help fine-tune your machine. Today, a simple phone call to our number can yield valuable advice within mere minutes or hours. Recognizing that ‘more heads are better than one,’ we prioritize offering uninterrupted service, seven days a week.

With prior coordination, we will establish an efficient communication channel that suits your needs and enables prompt issue resolution. In many cases, a video call can offer a more cost-effective solution compared to dispatching a technician on-site.

FINANCING

Setting up a knitting factory involves expenses, covering knitting machines, adequate space, corporate facilities, a skilled knitting team, and other essential equipment.

Drawing from our extensive experience, we’ve navigated this process numerous times and are eager to lend our expertise. We’ll collaborate to scrutinize your business plan and knitting factory project, evaluate your financial capacity, and engage with relevant organizations to secure financing.

Securing grants or managing critical administrative duties can prove challenging for many entrepreneurs. We’ve successfully orchestrated grant applications and facilitated technology financing through grants in the past.

Español

Español Italiano

Italiano Deutsch

Deutsch Čeština

Čeština